When it comes to fasteners, many different properties make certain fasteners better equipped for certain applications. In applications that require a secure joint, thread-locking fasteners are designed to prevent separating once the fastener is installed. These thread-locking fasteners are also sometimes referred to as prevailing torque fasteners according to ISO standards. Let’s explore the various types of thread-locking nuts and bolts.

Non-metallic Thread-Locking Fasteners

Non-metallic thread-locking fasteners are typically made from nylon, however, some material rubs off with each assembly or disassembly. Thus, these fasteners should normally be replaced after several cycles of assembly and disassembly. In addition, these fasteners are unsuitable for high-temperature applications as the material softens and the locking mechanism disappears.

Prevailing Torque Nuts

With this type of fastener, the locking mechanism is usually limited to a few threads in the middle or near the top side of the nut–rarely extending over the entire height. These mechanisms may take a variety of different designs, such as:

- A nylon ring attached to the top side of the nut;

- Elastic metal plates inside a nylon ring;

- A slotted locking element at the top of the nut;

- A nut with a slotted collar and attached spring that contracts within the collar;

- And many other designs.

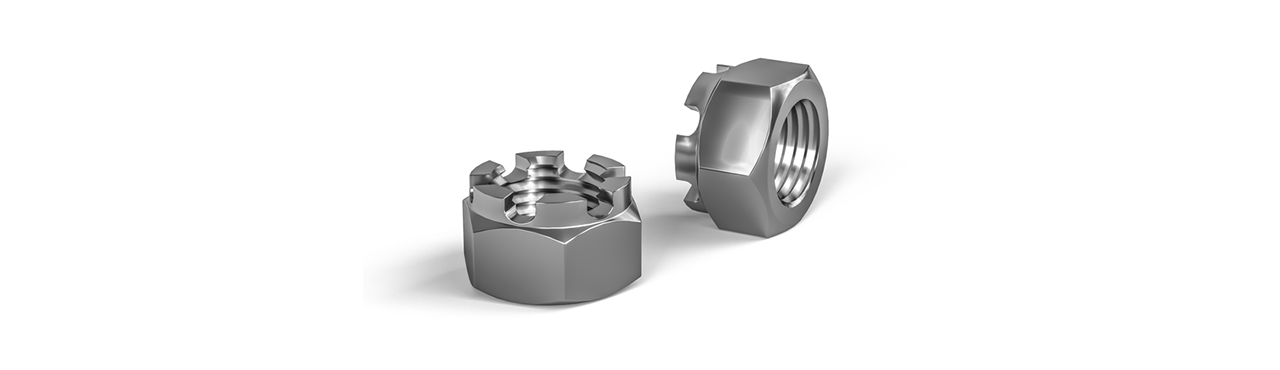

Slotted Hex Nuts

Single and dual-slotted hex nuts are fasteners that are slotted laterally from one (or both) sides. When a screw is inserted into the nut, the slot is pressed together, creating a partial pitch in the threads. However, these fasteners are only good for one assembly since the slots are widened. For future assemblies, new hex nuts would need to be used instead.

Center Lock Nuts

As its name suggests, these fasteners feature a locking mechanism in their central threads. Since the locking mechanism is in the center of the fastener, the mating thread can be engaged from either end of the fastener. These internal, distorted threads place greater resistances on the mating thread, creating a tight joint that can resist loosening caused by vibrations.

Brand-Name Lock Nuts

Various types of brand-name lock nuts have unique features. These include:

- Flexnut Lock Nuts: All metal and capable of withstanding extreme temperatures, vibration, and shock.

- Vargal® – All-Metal Lock Nut: Good for applications where superior anti-loosening performance is required.

- Spiralock Technology: Ideal for highly stressed and critical bolted joints.

- Hardlock Nut: Creates a powerful lock that can withstand loosening and shock.

Assembling Locking Fasteners

When assembling locking fasteners, screws are generally inserted from the bottom of the fastener where there is no locking mechanism. Center lock nuts and slotted hex nuts can be installed from either side of the fastener. For a full locking effect, the screw should be installed past the locking mechanism by at least 1.5 to 2 threads, otherwise, the screws may not be fully secured. Even with the locking mechanism, screws may become loose when exposed to vibrations even though the mechanism prevents them from unwinding.

With such a variety of locking fasteners, choosing the right one for specific applications can be difficult. Since the 1950s, One Monroe EFI has been a trusted supplier of sophisticated and specialized fasteners. Contact our experienced team today to learn more about the thread-locking fasteners we stock.